by Alexander Sauer and Abhinav Chugh*

- Access to affordable renewable energy and their deployment are key enablers for decarbonization of heavy industries.

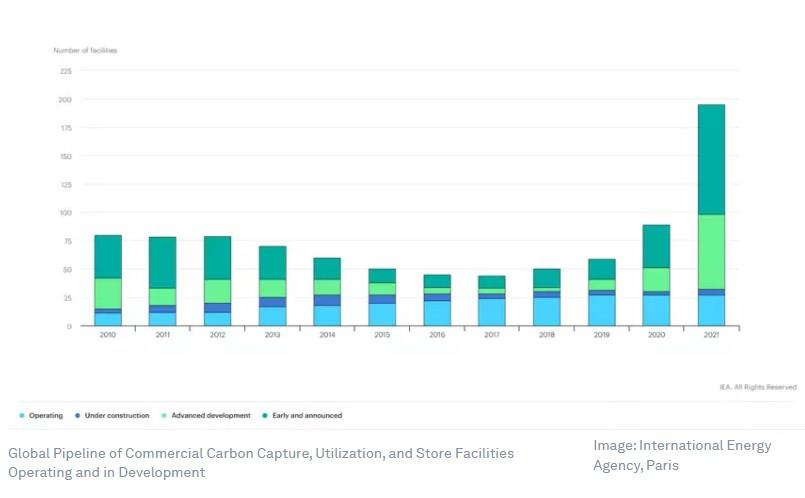

- Technologies required to clean up the most polluting sectors – such as hydrogen to reduce iron ore, green ammonia to fuel ships, or carbon capture and storage – are either not available or not yet commercially viable.

- There is a need to foster a market environment that rewards supply of low-carbon emitting technologies and circular products and promotes bio-based technologies.

In the Net Zero Emissions by 2050 Scenario, industry emissions fall 2.3% annually to 6.9 Gt CO2 by 2030 – despite expected industrial production growth. Industrial energy consumption has risen considerably in the past two decades - increasing an average 1% per year between 2010 and 2019, along with demand for industrial products and CO2 emissions. According to the International Energy Agency’s Industry Tracking Report 2021, in the Net Zero Emissions Scenario, growth in energy use needs to be limited to about 0.9% per year to 2030, despite expected expansion in industrial production.

Renewable energy and greater energy efficiency are the key enablers for decarbonization efforts of manufacturing and heavy industries. Renewable resources could also serve as raw materials for products with a lower carbon footprint and could be instrumental to close the carbon loop in the context of value chain circularity. Abundant renewable energy including low-carbon and renewable hydrogen as well as the respective infrastructure connecting energy and production hubs is a pre-condition to achieve an emissions-free industry.

Although both industry and governmental regulations increasingly support the expansion of renewables and related infrastructure, policy instruments that encourage their economically viable use would foster a more rapid deployment. This would require the recognition of all emission reduction potential initiatives in the form of programs and public funding support for the development and deployment of low-carbon emitting technologies (LCET).

Energy efficiency as a critical component to decarbonisation

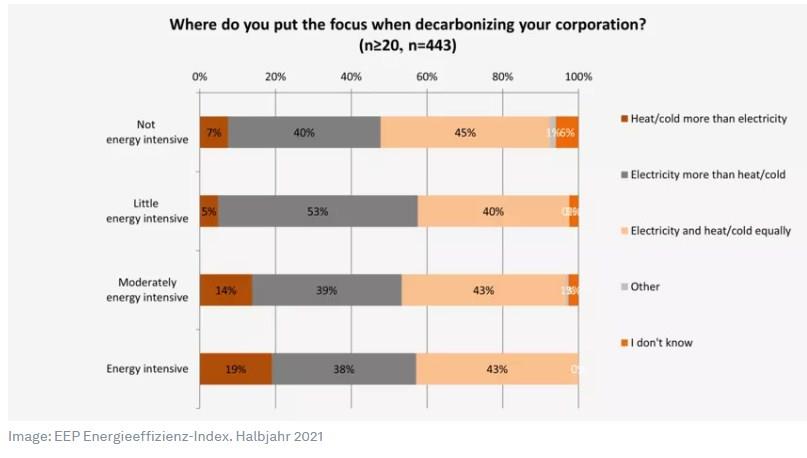

Energy efficiency refers to using less energy to perform the same task - that is, eliminating energy waste. Energy efficiency brings a variety of benefits: reducing greenhouse gas emissions, reducing demand for energy imports, and lowering our costs on a household and economy-wide level. Two thirds of industrial energy consumption goes into heat applications, but the focus is often on electricity. With increasing energy intensity, the importance of heat applications for decarbonization in companies increases.

Professor Alexander Sauer, Executive Director of the Institute for Energy Efficiency in Production at the University of Stuttgart, Germany and Fraunhofer IPA, believes the importance of energy efficiency has never been rated more highly by industry as it is now. We explore questions on the energy transition with Sauer, who developed the Energy Efficiency Index and is also leading the Kopernikus Project SynErgie, one of the largest scientific projects working towards the energy transition.

What led you to develop the Energy Efficiency Index? How does energy efficiency enable decarbonisation efforts in the manufacturing and production context?

Energy efficiency has been largely overlooked in early periods of energy transition planning. Our goal was to underline the importance of energy efficiency in general but also particularly in the manufacturing and production context. The production sector is important because it should not only manufacture goods efficiently but also take into consideration its’ impact on other sectors.

Reducing energy demand in production can help to decrease energy demand in general, thus, automatically increasing the share of green energy significantly. Increasing energy efficiency is a catalyst in gaining more cost control at the local level, making production more resilient in context of price shocks and security of supply.

The index aims to inform where the industrial sector is now, where it wants to be in the future, and what its plans and obstacles are to get there. There are still large knowledge gaps to bridge (e.g., cross-cutting technologies) and policymakers making important decisions need to be informed of these gaps to address their policies and funding adequately. The goal of this research is to help gather information and provide evidence-based advice for decision making to public and private sector stakeholders advancing the energy transition.

The promise of innovative technical solutions to fulfil our climate goals

What are low-carbon emitting technologies? Why are investments in these technologies important to fulfil the net-zero emissions objective by 2050?

Low-carbon emitting technologies (LCET) are referred to as innovative technical solutions that are characterized by a low emission intensity, compared to state of the art alternatives. In a way, they can be seen as best-in-class technologies with a focus on environmental impact. They should act as an economic substitutional technology while fulfilling the initial promise of performance.

As the renunciation of the general ideal of growth-led economics is not to be expected either in the short or medium term, we as a global community rely on the development of such technologies if our overall goal is to preserve a habitat for humanity which fosters biodiversity. Since the industrial sector is responsible for a significant share of global anthropogenic GHG emissions, there is an urgent need to lower resource input (and consequently emission output) of industrial production while meeting the demands of consumption in society.

Examples for LCET are manifold and include increase the utilization ratio of available resources (heat pumps, combined heat and power, etc.), decrease the primary demand for production factors (DC-Smart Grids, intelligent and digitized facility management), make use of inevitable emissions (carbon capture and utilization) or convert desired products from renewable resources (photovoltaic, geothermal heating, hydrogen, etc.). For more available technologies, you can refer to our study.

What policy changes could foster a market environment that rewards supply of low-carbon and circular products into our value chains?

All solutions here have a commonality - they either include minimum standards, reporting requirements or are market-driven systems. Generally, moving from punishment towards reward-systems could be helpful. A lot has already been achieved by regulation, however there is a need for a component that allows for plannability, especially regarding emission trading and emission-costs.

The “LEME-approach” (List of eligible manufacturers and equipment) refers to an approach, where technologies only qualify for funding or subsidies when they are among the best technologies within a category. E. g., only the top five most efficient pumps qualify for funding programs. Another approach are procurement rules that have to consider environmental components and not only financial and technical ones such as energy consumption and carbon footprint per unit. For the public sector, the new German government is considering introducing such an approach for their procurement. A challenge, however, is to forcefully impose this on private sector stakeholders. Instead, a solution would be to get the buy-in of these stakeholders by understanding their benefits of adopting such systems.

Circular economy is an emerging concept aiming to generate more distributed and inclusive systems which includes more repairability of products and availability of spare parts to reduce waste, along with treating waste as a design flaw. From a market perspective, supply shortages in interim products and raw materials are a challenge already and incentivize better recycling.

The development of a new product takes its time until it can enter the market. To ensure products which enable us to reach carbon neutrality, we need a system in which products must either display the embodied carbon footprint (pcf) and expected energy use along with repairability requirements, or even undergo testing for 2050 compatibility (EU net-zero goal). Such products, if awarded with a label confirming, could create incentives to accelerate the development of such efficient LCET even earlier (net-zero goal of Germany in 2045).

Creating the market conditions to unleash innovation

Considering the payback time and lifecycle costs vis-a-vis existing systems, we need to incentivize public funding and investments so that these technologies can become more competitive in comparison to fossil fuels. What opportunities could stakeholders tap into?

From our Energy Efficiency Index, we concluded that the support on the demand side needs to be optimized because it is more a question of deciding to invest the money than it is to get the funding (except for micro- or energy intensive companies). Support in easing the project planning costs, especially in reducing the investment risk could resolve some of these challenges. Additionally, reducing the public planning and approval process duration would also make a big difference.

Concerning lifecycle costs and payback time, it is more a systemic requirement to help companies to also consider the carbon costs avoided by adopting efficient technologies rather than only considering amortization based on investment- and operational costs. To reach net-zero emissions, it would make sense to optimize the cost effective mix of measures (including emission costs) for the target year instead of the traditional two to three years.

Various GHG compliance regulations are emerging in the context of the EU Green Deal, and the Renewable Energy Directive (RED). What sort of regulations or legislative measures do you anticipate from emerging economies and markets?

Emerging economies and markets need the space to develop and catch up with developed economies. At the same time, they could overleap all the emission intensive steps that the developed economies have taken. They need the means to boost these advancements to today’s feasible technologies and they need assistance in doing so. Legislation exists rather in conditional measures promised in the context of COP26 held in Glasgow, which means that they are based on financial and technology transfer support by the developed economies.

The biggest gap in regulation and policy is the foundational understanding that energy transition and becoming net-zero will only work if we put the necessary emphasis in local optimization, especially on the demand side. The demand side determines how much energy is used. Thus, controlling and optimizing energy-related and product-related emissions is vital.

Emerging economies have a stability incentive to create resilience in their energy systems. Being efficient pays off in many ways and the regulations and legislative measures needed in those countries are measures to support growth and stability of energy supply and transmission systems as well as their flexibility. There will, however, also be a market driven environment, where companies are pressured to adhere to global decarbonization standards (supply-chain requirements), otherwise they will not be able to sell products on international markets anymore.

Converting waste and residue into valuable products

What role does waste processing have in emissions reduction and savings?

In terms of resource efficiency, the first step is avoiding waste in production and designing products that can be reused or recycled as easily and effectively as possible. As the role of bio-based materials is set to increase in the future, this offers a further opportunity for climate protection: the possibility of creating GHG or carbon dioxide sinks. Along with GHG reductions, they are also urgently needed to achieve climate neutrality.

Creating carbon dioxide sinks is possible, for example, through HyBECCS processes, where energy is obtained from biogenic residual and waste materials in the form of hydrogen. The by-product of biogenic CO2 can be captured, stored, or reused as a raw material. Thus, new GHG emissions can be avoided but even more - their concentration in the atmosphere can be reduced. In order to be capable of exploiting this potential, it is necessary to ensure that environmental impacts of biomass cultivation and production of bio-based products can be monitored and controlled.

*Director, Institute for Energy Efficiency in Production (EEP), University of Stuttgart and Content and Partnerships Lead, Strategic Intelligence, World Economic Forum

*first published in: www.weforum.org

By: N. Peter Kramer

By: N. Peter Kramer